Why Rotary Unions Shouldn't Be Seen as 'Just a Commodity'

Key takeaways

- Rotary fluid sealing has very specific challenges that require experience and seal expertise to overcome

- Indirect costs associated with a product failure should be strongly considered when making the decision of selecting a rotary union supplier

- Be very cautious of going with the lowest priced option

When it comes to fluid sealing, taking shortcuts can mean risking your company's reputation

Across every industry, equipment manufacturers depend on suppliers for critically-sourced parts and components that have a significant impact on product functionality and reliability.

Selecting a supplier is a strategic decision and should begin with defining the most important criteria for evaluating a supplier. Typical criteria includes a combination of product quality, performance, pricing and experience.

Many businesses make the mistake of always choosing the lowest bidder.

While going with the lowest cost may make sense in the near-term, "low cost" often means low quality (both in product performance and support) which can put your company's reputation at risk.

Be aware of the risks of buying "knock-off" rotary union products

We are flattered by the numerous companies imitating our products, however, we feel responsible to educate buyers on the risks and true cost impacts of integrating low-grade components into their equipment.

These sellers typically flood the market with products designed, manufactured and assembled by those with little knowledge and expertise in rotary sealing. They have some spotty success when they get lucky but mostly leave a wake of failed products and poor performance.

DSTI is contacted weekly by OEMs either experiencing downtime or spending significant time resolving warranty issues and repairing damage to their reputation in the market — all lured by very low pricing.

Seriously, just let us know and we'll put you in direct contact with other companies to hear their experiences firsthand.

There are reputable options in the market that make rotary union products under a reasonable quality standard. However, we have heard from too many unsatisfied customers (many first-time buyers with limited experience with rotary unions) who were enticed by extremely low cost options.

The challenges of fluid sealing

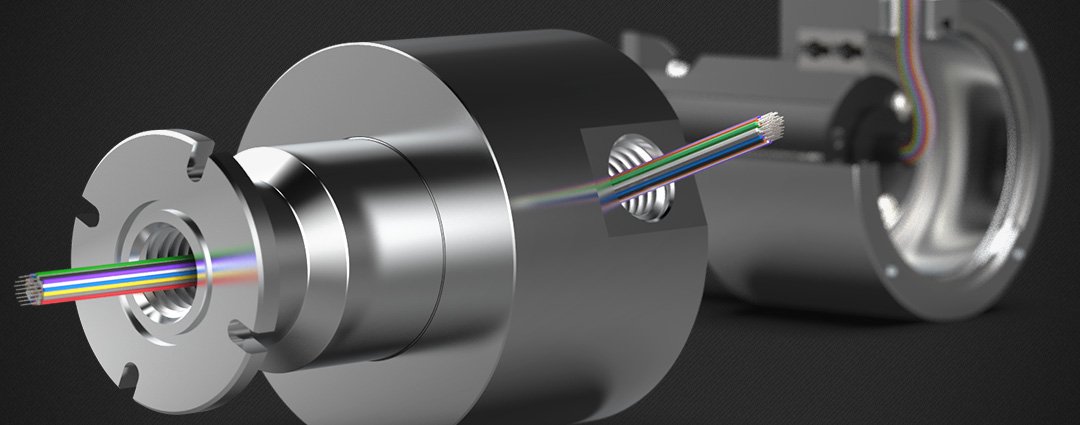

Rotary unions or swivel joints are often one of the most critical and overlooked components in your equipment. Their purpose is to provide an effective and reliable seal under pressure while transferring fluid (liquid and gas) between stationary and rotating points in your equipment.

The concept seems simple, but there are many factors that have a big impact on the performance and reliability of a rotary union including:

- Media type, pressure, temperature, flow rate and filtration

- Rotational speed

- Duty cycle and applied loads

- Torque limits

- Environmental conditions such as temperature, exposure, shock and vibration

- Duration between maintenance intervals and serviceability

These application parameters are necessary to determine the right design approach and material compatibility for the shaft, housing, seals, bearings and other components.

Partnering with fluid sealing experts

Equipment failure can give rise to safety, environmental, productivity and financial issues (some even catastrophic).

Partnering with a reputable supplier is essential for keeping your equipment running as it was designed — which is ultimately what your customers want and expect.

DSTI has been a key partner to OEMs since 2002, developing reliable solutions for most any sealing need in every industry, environment and application. No, really! We have rotary unions being tested on the International Space Station and others that are reliably performing at 10,000 PSI, nearly two miles under the sea.