Heavy Equipment Solutions Underground &

Surface

Drilling Equipment

Mining and drilling operators rely on DSTI products to tackle a wide variety of demanding jobs for optimal productivity and greater component longevity.

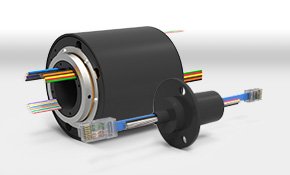

Down-the-hole (DTH), in-the-hole (ITH) and blasthole drill rigs are integrated with a rotary union (swivel

joint) for delivering a consistent and dependable supply of compressed air to the DTH percussion mechanism

(hammer). Air travels from stationary hoses on the rotary drill, through the rotating drill string, and into

the hammer. The fast hammering action breaks hard rock into small flakes that are blown clear by the air

exhaust from the hammer.

Since 2009, DSTI has supplied more than 750+ field-proven, air swivels for

DTH, ITH and blasthole operations used in quarries, open pit mining, underground mines, construction,

exploration, oil and gas, and geo-thermal drilling operations. Each featuring exclusive sealing technology

and a heavy-duty construction aimed at eliminating common industry failures.

To ensure maximum

uptime, DSTI swivels can be designed for quick and easy serviceability. In a matter of minutes technicians

can gain access to replace the swivel’s main seals; and in most cases while still installed in the

equipment.

In addition, DSTI also provides custom rotary unions for other applications that require

unrestricted rotation while transferring air, water, mud, hydraulic oil and electricity.

Applications

- Down-the-Hole (DTH) Rigs

- In-the-Hole (ITH) Rigs

- Rotary Blasthole Rigs

- Jumbo Face Drills

- Load / Haul Dump Loaders

Technical Specifications

- Supplied More Than 750 Air Swivels for Down-the-Hole (DTH) Drilling Applications

- Design Leverages DSTI's Extensive Sealing Technology Library

- Proprietary Sealing Surface Treatment Offers Multiple Rebuilds

- Seals are Compatible for Air, Water, Hydraulic Oil and Grease

- Designed to Integrate Directly Into Existing Equipment