Standard & Custom Slip Rings

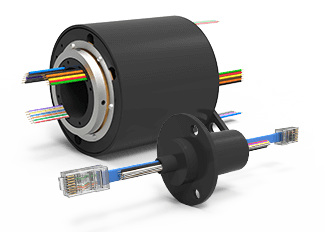

Standard

Slip Rings

Fast, flexible solutions that easily integrate directly into your equipment.

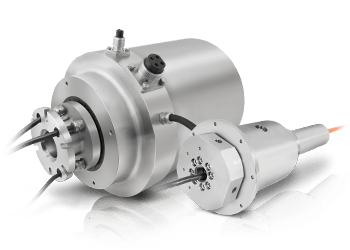

Fluid +

Electrical

We offer complete fluid + electrical integration to meet your needs.

- Standard (In-stock) & Custom Solutions

- Fully Assembled, Tested & Qualified

- High Performance Seal Technology

IP65 Slip Ring

Enclosure

Ultimate protection against water and dust ingress.

- Direct Spray & Splash Protection

- Dust & Dirt Protection

- Continuous Rotation Up to 250 RPM

Overview

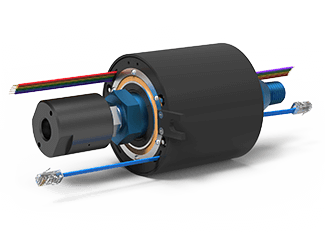

DSTI slip rings (electrical joints) reliably transfer data and power from stationary sources to rotating parts.

Our slip ring products are used across a wide range of industries including factory automation, heavy equipment, machine tool, packaging, medical, oil and gas, defense, and aerospace.

We offer standard electrical slip ring product lines that feature high-performance brush technology and are grouped by design type and circuit configurations.

If our inventory of standard slip ring products isn’t a fit for your project, we can provide a custom-tailored slip ring solution designed to meet the exact circuits, ratings, and design parameters required for your application.

Need to transfer fluid along with data and power? We can help select a reliable integrated fluid and electrical solution that can be customized to meet your exact requirements for fluid, power, signal, and/or data transfer.

Slip Ring FAQs

What is a slip ring?

An electrical slip ring is a device used to transfer power and data from a stationary to a rotating structure. Slip rings can provide continuous or intermittent rotation while transmitting power and data - simplifying operation, improving application performance, and eliminating risk of damage to wiring between movable parts. See Electrical Slip Rings

How do I choose a slip ring?

Proper selection of a slip ring solution requires details about your application's operating parameters including total circuits, voltage and amps per circuit, operating speed, and mounting type. A good place to start your search is with our Standard Slip Rings. If you are confident that a custom / modified solution is most likely required or need assistance in your selection, contact us to Get Started. Our experts are here for you.

Do you offer electrical slip ring / fluid rotary union combination assemblies?

Yes, DSTI fluid rotary union and electrical slip ring technology can be integrated together into one complete solution for fluid, power, signal, and data transfer. We offer both standard (in-stock) assemblies and custom solutions designed to meet your exact requirements. For more information see Fluid + Electrical Solutions

Do you offer custom slip rings?

Yes, we work directly with our slip ring partners to design custom solutions to meet your exact electrical requirements. For more information please see Custom Slip Rings

Are DSTI slip rings waterproof/dustproof?

DSTI standard slip rings are IP51 rated, meaning they offer limited dust and condensation protection. We offer an optional IP65 Rated Slip Ring Protective Enclosure for enhanced protection against water, dust and damage. For additional questions about waterproof/dustproof slip ring solutions, contact a member of our Sales Support Team to discuss options.

How do I install/mount my slip ring into my equipment?

CAUTION: Because of possible geometric mismatching between the customer’s application

and the slip ring, “hard mounting” of both ends of the slip ring (i.e., securing the rotor and stator such

that there is NO floating during operation) is not recommended and may cause premature

failure.

To mount capsule slip rings:

1) The slip ring

capsule is designed to be flange-mounted with the barrel cantilevered.

2) The rotor

must be driven with a flexible coupling (i.e. rubber tubing, helical or bellows-type) to accommodate any

eccentricities in the mounting. The rotor leads can be used as a flexible coupling for operation at speeds

up to 5 RPM.

3) Use (3) screws with flat washers to mount the slip ring. If lock

washers are also used, flat washers should be mounted between the lock washers and the flange. (Hardware

not included)

4) The slip ring is not designed to bear the weight of the equipment to

which it is connected. Rotating equipment should be secured so that no axial or radial load is applied to

the slip ring rotor.

5) The slip ring should be protected from dust and moisture. For

outdoor installations, the slip ring should be installed in a weatherproof

enclosure.

6) Secure all leads so that they do not rub against any surface as the

equipment rotates. Care should be taken when routing and securing the leads so that no side loading of the

slip ring occurs.

To mount through bore slip rings:

SHAFT MOUNTED

UNITS

1) Position the slip ring in the desired location and equally tighten

both set screws to the shaft on each end of the union. Torque to 25 lb-in.

2) Route

the wiring and make the necessary connections. Do not allow the wiring to restrict free rotation of the

slip ring.

3) Position a screw or dowel (not supplied) in the anti-rotation

tab.

FLANGE MOUNTED UNITS

1) Align the mounting holes in the

flange to mounting base and install flat washers and thread forming screws (NOT SUPPLIED) for plastic.

Securely tighten screws.

2) Route the wiring and make the necessary connections. Do

not allow the wiring to restrict free rotation of the slip ring.

3) Position a screw

or dowel (not supplied) in the anti-rotation tab.

Is there a quantity price break if I order multiple units?

To discuss quantity price breaks, contact a member of our Sales Support Team.

Can I combine multiple circuits to get higher current/amps?

In some cases it is possible. Please contact a member of our Sales Support Team to better understand your application needs.

Are DSTI slip rings explosion proof?

No. DSTI standard slip rings are not explosion proof. If your application requires an explosion proof slip ring, contact a member of our Sales Support Team to discuss custom slip ring options.

Can I run EtherCAT/Profibus/Profinet/USB/Cat5/Cat6 with DSTI slip rings?

There are almost endless options for transferring power/data with electrical slip rings. Contact a member of our Sales Support Team to discuss your electrical needs. If an option is not available with one of our standard product offerings, we can develop a custom solution to meet slip ring configuration needs.

What connection type do the Ethernet cables use in your Ethernet slip rings?

All Ethernet cables are terminated with Registered Jack 45 (RJ45) connectors using T568B wiring standards.

Do you offer different lead lengths?

Some of our slip rings can be custom ordered with longer lead lengths. Contact a member of our Sales Support Team to discuss your application needs.

What is the gauge of the wiring?

Wire gauge varies by product and current. Generally, all 2 amps are 26-28 AWG, 5 amps are 20 AWG, and 10 amps are 16 AWG. For specific wire gauges, download our Slip Ring & Wire Color Code brochure.

What if my voltage rating is slightly higher than your recommended voltage?

There is a small degree of padding built into the listed maximum voltage ratings. Contact a member of our Sales Support Team to discuss your application needs.

Are DSTI slip rings UL rated?

No. DSTI slip rings are not UL rated.

What frequency (Hz) are DSTI slip rings rated for?

DSTI standard slip rings are rated for 0 - 150 mHz. If your requirements fall outside that range, contact a member of our Sales Support Team to discuss other options.

Are DSTI slip rings certified to military standard/MIL-STD/MIL-SPEC?

No. DSTI slip rings are Commercial - Industrial Grade.

Can DSTI slip rings work with RF signals?

No. RF signals are much more complex than DSTI standard slip rings can handle.

What temperature are the leads rated for?

The slip ring assembly is rated to 176°F [80°C]. The leads are rated to 221°F [105°C].