Engineering &

Simulation

DSTI's Engineering team leverages years of experience and a deep knowledge of engineering disciplines to provide fast, innovative design solutions.

At DSTI, working side-by-side with our customers allows us to deliver maximum value, provide innovative

solutions, and identify and mitigate risks at the earliest stages of a project. Our engineers are constantly

developing new designs and using new materials across a wide spectrum of diverse environments, from

cleanrooms and oil fields to subsea and space.

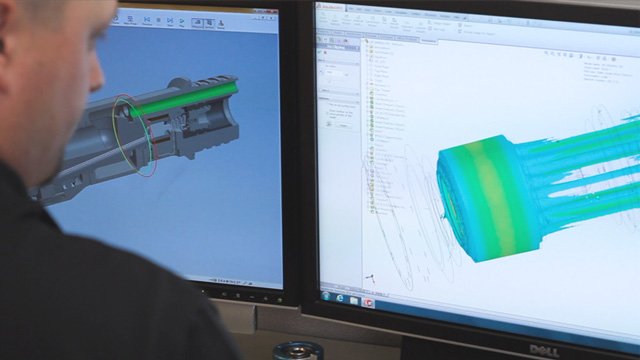

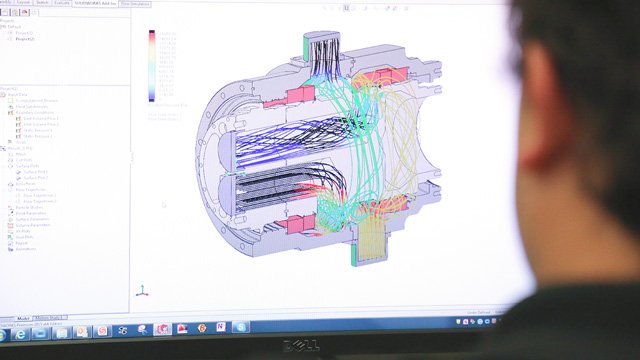

DSTI's simulation and verification capabilities allow

engineers to evaluate designs using a variety of metrics including loads, forces, pressure and pressure

loss, torque, flow, friction and more, to find areas of improvement while ensuring customer requirements are

met.

As a trusted provider to industry leaders across the globe, we'll help find shortcomings at

early stages, avoid expensive re-design, reduce cost and mitigate risk to help bring your product to market

faster.

Overview

- Design Product Models & Drawings using Solidworks 3D Computer Aided Design (CAD)

- Validate Product Performance & Safety Factors Using Finite Element Analysis (FEA)

- Simulate Fluid (Either Liquid or Gas) Flow & Pressure Computational Fluid Dynamics (CFD)

- Verification of Process Simulation, Calculation & Design Drawings

- Complete Traceability & Part Serialization with Manufacturing ERP System

- Compliance to Customer Specifications & Industry Codes/Regulations