Welding &

Fabrication

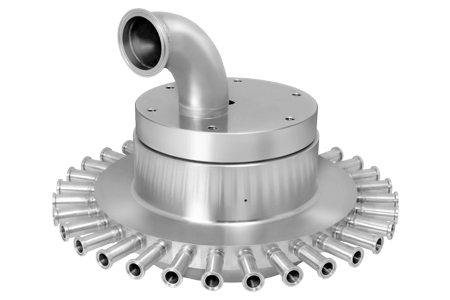

DSTI's certified welding team specializes in complex structural assemblies and high pressure piping components for a large variety of base metals.

DSTI is ISO 9001 certified, offering a wide range of precision welding and fabrication services for

defense, aerospace, oil and gas, medical and other industries where quality assurance documentation is

required.

With experience in Gas Metal Arc Welding (GMAW), Flux Core Arc Welding (FCAW), Gas

Tungsten Arc Welding (GTAW), and Shielded Metal Arc Welding (SMAW), our certified welders take pride in

their work for consistent, high-quality and dimensionally accurate fabrications, day after day.

Our

in-house engineering expertise, CWI personnel, code specific PQR-WPS creation, knowledge of materials, a

wide procurement network, in-house machining, fabrication, assembly and testing as well as a dedicated

project management team allows us to provide an optimized overall package to our clients no matter the size

or scope.

Overview

- Welding Procedures Certified To Codes Including ASME IX, AWS, DIN, API, B31.1, B31.3, ABS, DNV, NACE, & Others

- Certification Packages Upon Shipment Including; Base Material MTR's, Weld Filler MTR's, WPS Records, PQR Records, Welder Qualifications, Calibrations, Welding Operator, Stress Relief, Destructive & Non-Destructive Testing, Pressure Testing, & Coating Systems To Customer Requirements

- Close Tolerance, Complex Weldments with CMM Dimensional Reporting

- Distortion Control Fixtures for Dimensionally Consistent Finished Product

- Pre-Weld & Post-Weld Machining Services

- In-Process Examinations & NDE Certification Reports

- Customer & Third Party Witnessing & Qualifications

- Weldment Positioning up to 6,000 Lbs

- Experience with Weldments up to 57,000 Lbs